Leku-Ona boosts its formed tube business with new investments that will enable it to specialise in bending complex tubes, such as the INCONEL type

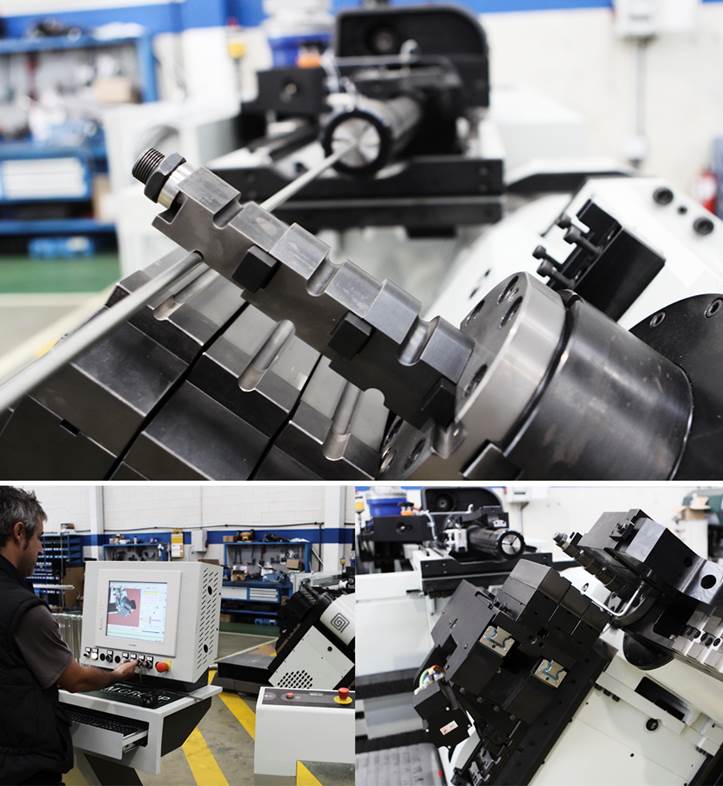

Leku-Ona is always keen to innovate and adapt to the current market, and as part of this objective, it has boosted its formed tube business, investing in advanced machinery, including a BLM E-TURN (ET 52) electric bender that can bend tubes with diameters of up to OD: 52 mm. This will enable Leku-Ona to provide global tube-bending solutions to companies from different sectors who require this type of service.

The combination of Leku-Ona’s experience and its modern forming machinery means there is no more deformation or loss of the tube’s mechanical properties. Not only that, but the operation can be completed in just a few minutes with excellent results.

INCONEL TUBE FORMING

Among the most complex tube alloys to bend we find the INCONEL alloy (nickel-chromium-iron), which is a common material used in engineering applications that require high resistance to corrosion and heat. This alloy also has excellent mechanical properties as well as an interesting combination of high hardness and good machinability, although it is unusual to find companies that master the bending process of INCONEL tubes.

Leku-Ona has a wide range of machines for bending tubes at its facilities, which enables it to work with diameters ranging from OD: 6 mm up to OD: 60 mm to bend carbon steel, stainless steel, copper, brass or INCONEL tubes, meaning the hydraulic facilities last longer.

In fact, the high nickel content offers resistance to corrosion from many organic and inorganic compounds, and it also makes it virtually immune to cracking due to chloride ion stress corrosion. Chromium awards it resistance to sulphur compounds and also resistance in oxidation conditions at high temperatures or in corrosive solutions.

In fact, the high nickel content offers resistance to corrosion from many organic and inorganic compounds, and it also makes it virtually immune to cracking due to chloride ion stress corrosion. Chromium awards it resistance to sulphur compounds and also resistance in oxidation conditions at high temperatures or in corrosive solutions.

Leku-Ona’s extensive experience in tube forming has enabled the company to offer new solutions in a wide range of industrial uses in sectors such as: renewable energies, ship-building, agricultural machinery, public works machinery, machine tool, forestry machinery, automotive industry, greasing or recycling, among others.

TUBE BENDING MACHINES AT LEKU-ONA:

- 1 BLM E-TURN (ET 52)

Maximum bending capacity from OD: 6 mm up to 52 x 2 mm.

All-electric machine with right and left bending in process and 3D graphic visual programming (VGP3D)

- 2 BLM-SMART

Maximum bending capacity at OD: 22 mm in steel tube and up to OD: 28 mm in copper, brass or aluminium tube

- 1 BLM HYDRAULIC NCS832

Maximum bending capacity up to OD: 30 mm.

- 1 AMOB MDH 60

Maximum bending capacity at OD: 60 mm.

- TUBE END-FORMING MACHINES

Please do not hesitate to contact us at | T +34 943 74 34 50 | E leku-ona@leku-ona.com for further information.

Dejar un comentario

¿Quieres unirte a la conversación?Siéntete libre de contribuir!