New treatment of connectors DIN2353

Leku-Ona offers connectors DIN2353 manufactured and treated with the new coating processes that offer high resistance to salt spray. Since 2010 we have developed a research process that was based on the use of treatment with 320 A3C resistance. This process evolved into A3B (CrVI-free) and then to ZnNi (720 hours). Currently, it has begun to implement a new treatment called ZnNi NEW which is giving us high performance corrosion arriving at 3000 hours

APLICATIONS.

- Whenever a high corrosion resistance is required

- Temperature changes do stress additionaly

ADVANTAGES

- High corrosion resistance of the coating and base material

- Capable for flaring and bending

- Log term protection, even under thermal stress

- High availability

- Low maintaining costs within the application

TECHNICAL DETAILS

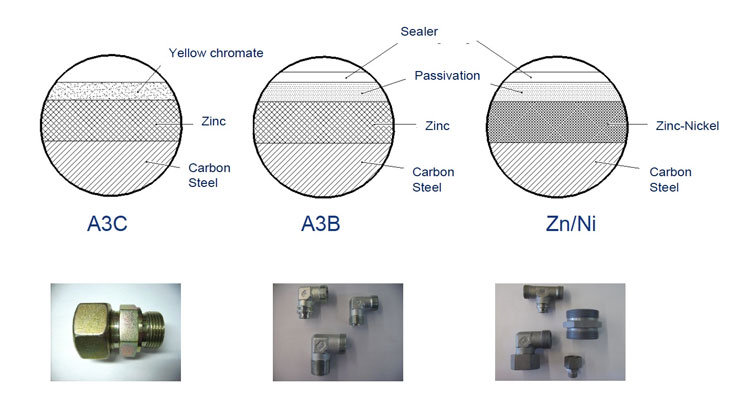

COMPARISON OF LAYERS

This chart shows a comparison of the type of treatment in the various processes A3C, A3B and Zn / Ni

SALT SPRAY TEST

Description:

- The following pictures indicate the corrosion resistance of Volz Zinc-Nickel

- plated parts with sealer

- Within the galvanisation process, these parts got handled in a drum

Indication of corrosion:

- Parts with assembled nuts show red rust after 1.872 hours

- This is a forced result as the salt water couldn‘t disappear at this point

- Other parts, where the salt water was able to disappear (as required by the ISO

- 9227:2006), show red rust within the band of 3.072 / 3.216 / 3744 hours

168 HOURS

1032 HOURS

2064 HOURS

3192 HOURS

5280 HOURS

Dejar un comentario

¿Quieres unirte a la conversación?Siéntete libre de contribuir!